How to choose the best LED strip lights?

Before buying LED strip lights, there are many factors that you need to consider, such as led light brightness, waterproof grade, working voltage, etc. Maybe you only know a certain point or part of the answer. How to choose the best LED strip light based on the only information available? This is the main purpose of this article, to answer your doubts when you start with LED light strips.

Before buying LED strip lights, please ask yourself :

1. Where do I want to place the LED strip lights? Indoor or outdoor? Non-waterproof or waterproof?

2. How much LED brightness do I need?

3. The working voltage is available?

4. How long is the LED strip light suitable for my project?

5. Do I need an LED light controller to adjust the LED color and brightness?

6. How to power the LED strip lights?

1. Where do I want to place the LED strip lights?

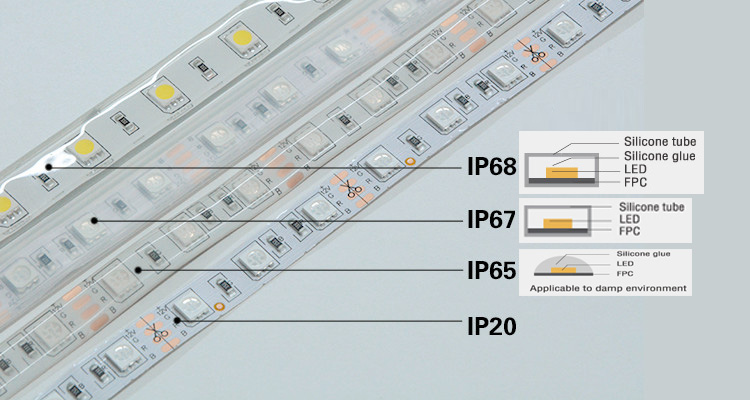

The place where the led rope light is used determines the waterproof level of the light strip. Generally speaking, IP20 and IP65 led strip lights are used indoors, IP67 and IP68 led strip lights are used outdoors. For those who see the waterproof rating for the first time, IP20, IP65, IP67, and IP68 are a little strange. What do they mean?

IP means ingress protection. The first number in IPXX indicates the level of dustproof and foreign body intrusion prevention of the led tape light, which is represented by 0 to 6. The second number indicates the moisture-proof and air-tightness of the led strip to prevent water penetration, which is represented by 0 to 8. The higher the number level, the stronger the protection.

| Dustproofing Level | Waterproofing Level | |

| 0 | No Production | No Production |

| 1 | Prevents large solids from entering | Unaffected by water droplets dripping onto the outer covering |

| 2 | Prevents medium-sized solids from entering | Unaffected by water droplets dripping onto the outer covering when the outer covering tilts at 15 degrees |

| 3 | Prevents small solids from entering | Prevents splashing water from seeping in |

| 4 | Prevents solids larger than 1mm from entering | Prevents sprayed water from seeping in |

| 5 | Prevents harmful dust from accumulating | No damage whatsoever if you wash it with water |

| 6 | Completely prevents dust from entering | Prevents big waves from seeping in |

| 7 | Can be used to resist penetration by water for short periods of time | |

| 8 | Soaks for a long time under a certain amount of pressure |

IP20 is non-waterproof. The flexible printed circuit board of the rope lights is naked and can not touch the water. And you need to be careful that do not to damage the led strip light parts, otherwise, it will cause a short circuit. If you plan to install LED strip lights in the bedroom, living room, cabinet, kitchen, or stair, you can choose IP20 led strip lights.

The IP65 led strip has a layer of glue to cover the parts. It is an upgraded version of IP20. It is splash-proof and can be used in humid environments, but cannot be immersed in water and is not suitable for outdoor use. In places where indoor tape lights will be splashed by water, such as kitchens or bathrooms, IP65 led light strips should be selected.

IP67 led strip uses a silicone sleeve or heat shrink tube to encapsulate, which is suitable for outdoor environments. Note that the IP67 light strip cannot be soaked in water. The waterproof rating of the led neon lights we are familiar with is also IP67.

IP68 is the highest waterproof grade of led strip lights, the light strip is completely sealed by the material, is available for outdoor use, and can be placed in hot and cold environments. If you want to make your swimming pool more cool with led strips, it must be an IP68 light strip.

Related: What are led neon lights?

2. How much brightness do I need?

LED brightness is normally talked about with density and lumen.

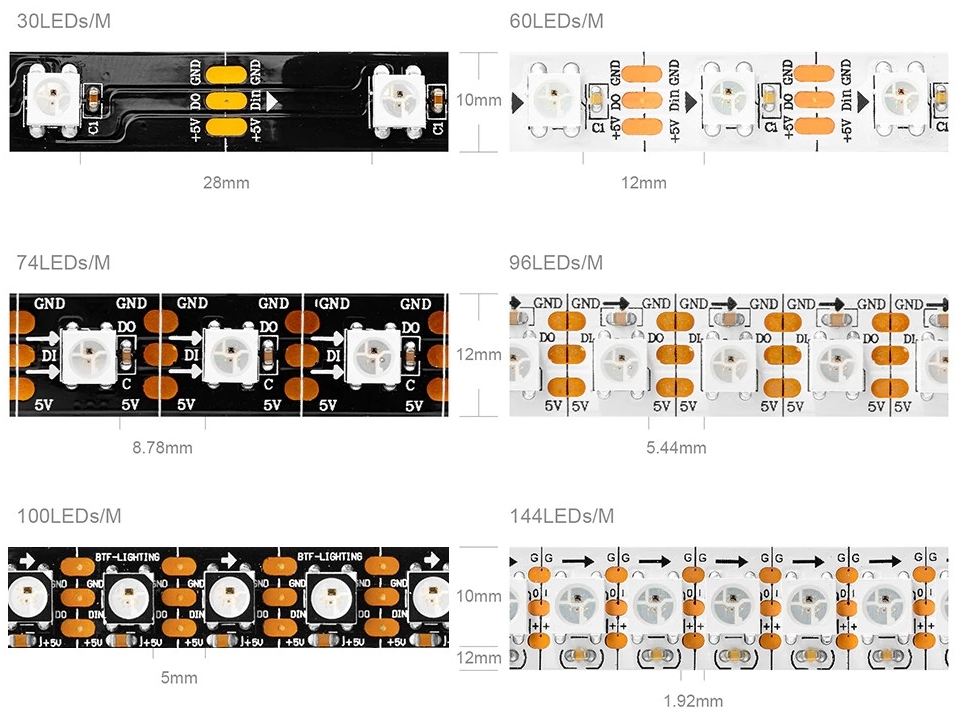

►LED density

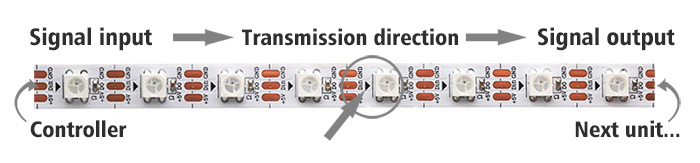

The density of the led light strip refers to the total number of LED lights on the strip. An led light strip usually indicates the total number of LED lights in 5 meters and the number of LED lights per meter. The denser the density, the more uniform the light distribution of the led strip, because the light-emitting angle of each SMD LED light is 120 degrees.

There are low-density(30-72 LED lights), medium-density(72-120 LED lights), and high-density(above 120 LED lights).

Multiple-row led tape lights can tolerate higher densities. Still not satisfied with the density of the single-row led strip, please choose the multiple-row led strip lights. Of course, if there are multiple rows of led strip lights, there will be ultra-thin led strips. If you don't want the led tape light to be too wide or the installation environment is narrow, don't miss it.

If you desire the led tape light to be the main lighting source or the lighting area is large, maybe high-density is suitable for you. On the contrary, the space is small and you don’t have many requirements of brightness, you can choose low-density or medium-density. It entirely depends on yourself.

►LED lumen

The lumen of the led light strip is closely related to the type of LED chip. The LED chip name is named after the LED size. Each chip type has its approximate lumens, but the lumens of specific led strips will be slightly different. If you are very concerned, you can check the specific lumens in the led strip specifications.

|

Lumen/Meter = Lumen/LED x Density/Meter Lumen/5M = Lumen/LED x Density/5M Lumen/Ft = Lumen/LED x Density/Ft |

SMD5050 and SMD2835 are the most commonly used chips. Among all SMD LED chips, SMD5050 and COB support color changes, such as the familiar RGB led strip lights. Other chips are white light, including single white light and dual-color temperature white light.

If you want higher lumens, in addition to looking at the LED chip, you must also pay attention to the density of the light strip. The denser the density, the higher the lumen. It is worth noting that high density and high lumen require high heat dissipation and high power.

How much brightness do I need? I believe you already have the answer. If you still have doubts, you can contact us and we will help you choose your best brightness.

|

LED Chip |

Lumen/LED |

Density/Meter |

Lumen/5M |

Density/Meter |

Lumen/5M |

Wattage/LED |

Voltage |

|

6-7lm |

30 |

900-1050lm |

60 |

1800-2100lm |

0.1W |

24V |

|

|

7-8lm |

30 |

1050-1200lm |

60 |

2100-2400lm |

0.1W |

12V/24V |

|

|

10-12lm |

30 |

1500-1800lm |

60 |

3000-3600lm |

0.1W |

12V/24V |

|

|

7-8lm |

30 |

1050-1200lm |

60 |

2100-2400lm |

0.08W |

12V/24V |

|

|

14-16lm |

30 |

2100-2400lm |

60 |

4200-4800lm |

0.2W |

12V/24V |

|

|

20-22lm |

30 |

3000-3300lm |

60 |

6000-6600lm |

0.24W |

5V/12V/24V |

|

|

22-24lm |

30 |

3300-3600lm |

60 |

6600-7200lm |

0.5W |

12V/24V |

|

|

22-24lm |

30 |

3300-3600lm |

60 |

6600-7200lm |

0.5W |

12V/24V |

|

|

3-4lm |

30 |

450-600lm |

60 |

900-1200lm |

0.02W |

5V/12V/24V |

Related: What is COB?

How to choose the right color for your led strip lights?

Ultimate guide to choosing the right addressable led strip

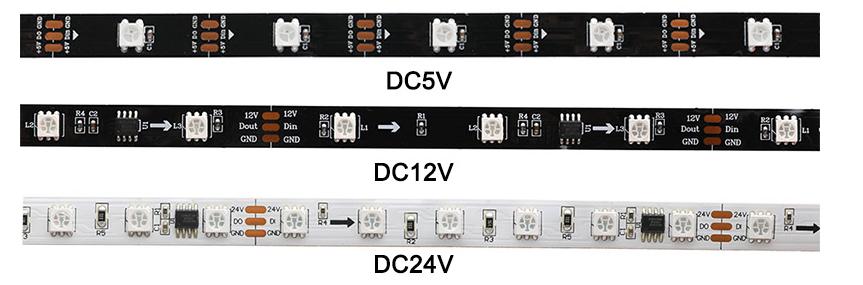

3. The working voltage is available?

LED strips are mostly low-voltage strips, with 12V and 24V led strips being the most common. In our low-voltage led strip lights, in addition to 12V and 24V, there are 5V, 36V, and 48V led tape lights.

36V and 48V led strip lights are constant current led strips with no voltage drop over long distances, and the color and brightness of the led light strip are always consistent. This is the biggest feature of the constant current led strip, and it is also to compensate for the voltage drop of the low-voltage led rope light.

5V VS 12V VS 24V LED strip

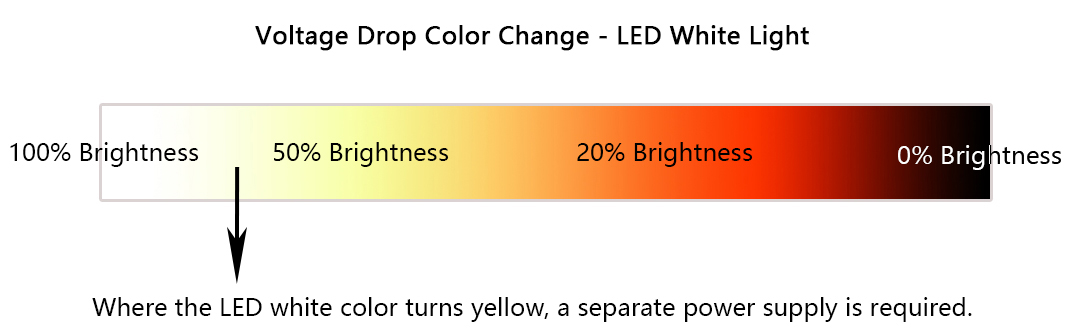

As mentioned above, low-voltage led strip lights have a voltage drop. Voltage drop refers to the attenuation of the voltage during transmission, which is manifested as the color and brightness of the same strip are inconsistent. The voltage drop of the white light led strip will have the following performance. First, the brightness will decay with the length, and then the color will also change, from the first white to yellow, then to red, and finally, the light disappears. Different voltages have different solutions for voltage drop. But in the end, it is to provide sufficient power for the led strip.

|

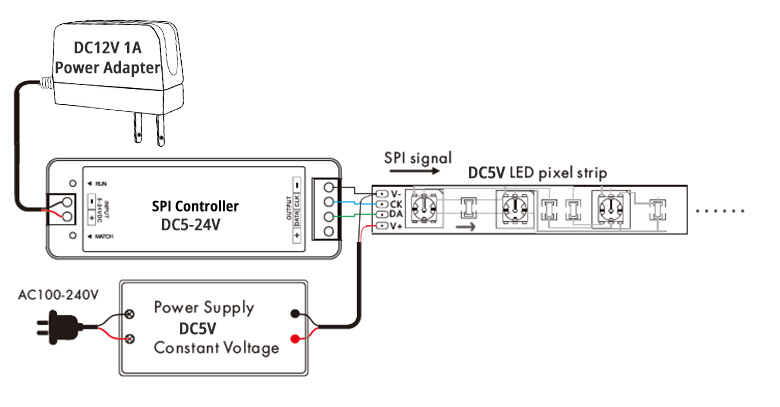

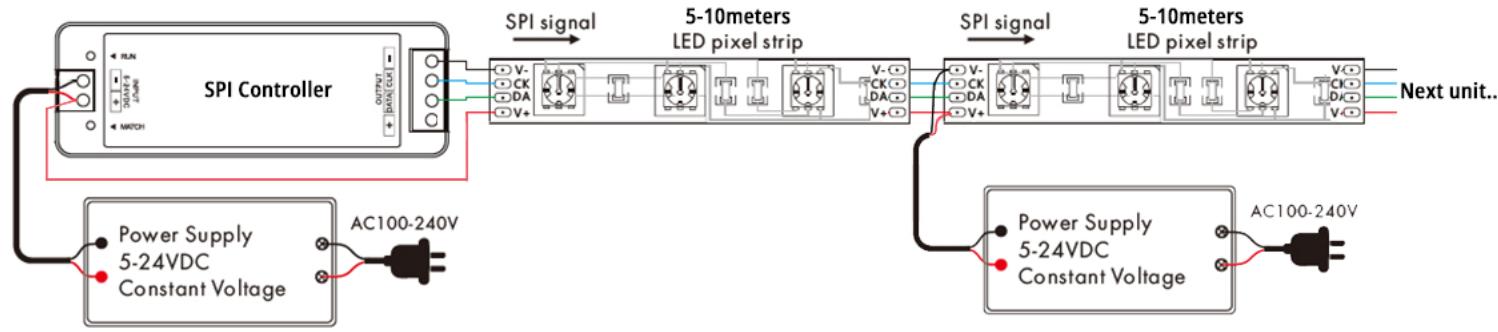

5V led strip lights have a voltage drop of five meters, and the cutting unit is an LED light, which can be more accurately cut to the length you need. And the 5V led strip needs a power supply at both ends to resist the voltage drop. 12V led strip lights are no voltage drop in 5-7 meters and cut 3 LED lights as a cut unit. The 12V led strip is powered at one end of five meters and needs to be powered at both ends for 10 meters. 12V light strips are also used in cars and boats. 24V led strip lights have no voltage drop in 8-10 meters, and can only cut 6 LED lights at a time. If you cut within the cut line interval, the LED lights in this area will not work. A 15-meter 24V led strip requires an led power supply at both ends, and a 10-meter strip can be powered at one end. |

The higher the voltage, the stronger the resistance to voltage drop, and the longer the operating length alone. However, the cutting accuracy will be reduced. The length of your project is long, 24V led strip light is selected. A constant current led strip with no voltage drop would be even better, if you like it. For cutting accuracy, choose the 5V led strip light. The 12V led strip is centered between these two points, so if you really don’t have a clue, you can try the 12V led strip light.

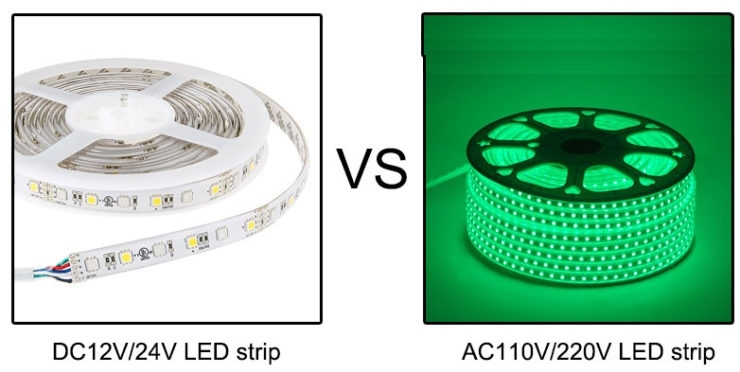

AC VS DC

High-voltage led strip lights are also a large category of led strips. There are single color AC 110/220V led tape lights and high voltage RGB led strips according to the led color.

Alternating current is transmitted from the power grid. The power is large and the transmission distance is long, but it is not suitable for contact with the human body and has a great safety hazard. It is recommended to install the high-voltage led strip in a place out of reach, and the high-voltage led tape light is not easy to maintain.

The direct current is stable, but the transportation distance is short. Low voltage is safe and harmless to the human body. 36V is the human body safety voltage. Many electronic devices use low voltage, which will not damage the internal electronic precision parts. The most obvious thing about low-voltage led light strips is the voltage drop. We have already mentioned the voltage drop above, so I won't elaborate on it here.

In short, low-voltage led strip lights are recommended for household lighting or decoration, and high-voltage led strips are recommended for professionals.

Related: How to cut led strip lights?

How to connect led strip lights?

4. How long is the LED strip light suitable for my project?

The LED strip light length is typically 5 meters/16.4 feet. Length is not a big problem actually because LED strip lights can be cut and connected. However, note that only led strips of the same specification can be connected together. The 12V led strip light works together with the 24V led strip light. Either the 12V led strip will burn out or the 24V led strip will not light up.

There are several led light strips that support short lengths such as 0.5 meters/1.64 feet, 1 meter/3.28 feet, and 2 meters/6.56 feet.

For ultra-long lengths, you can purchase multiple led strip lights for installation, or directly choose ultra-long constant current led strips, which will save a lot of wiring costs and make installation easier. Of course, which one to choose is completely up to you, and I am just providing suggestions. Regarding the wiring of multiple led strips, we will write in a follow-up article, so stay tuned.

The most important point is that we can provide you with customized services. Please contact us if you don't find the right length.

5. Do I need an LED controller to adjust the color and brightness?

If you want to change the brightness and color of the LED lights, an LED dimmer or an LED controller is essential for your project.

►Single color led strips and dual white led strips should be equipped with LED dimmer.

The single color led light strip is not boring and tasteless. The brightness of the led rope light can be adjusted arbitrarily from the brightest to the darkest by installing an led dimmer. Generally, the ordinary led dimmer is a knob button, and you can get the most suitable brightness by rotating the button. Of course, mobile phones, remote controls, and panel controls can also operate the led dimmer.

It is a huge project to fully understand all LED dimmers. Because there are so many types of LED dimmers, Triac dimming, 0/1-10V dimming, DALI dimming, DMX dimming, and PWM dimming. I believe you are stunned when you see so many types of LED dimmers. Triac dimming and 0/1-10V dimming are briefly mentioned in the article about led controllers. If you are interested, you can click to learn more.

Regarding LED dimming, in fact, you only need to understand that it ultimately achieves the function of adjusting brightness through different control methods. It's just that different dimming technologies have different precautions. Of course, if you feel that the current brightness of your led tape light does not affect you, you do not need to install an LED dimmer.

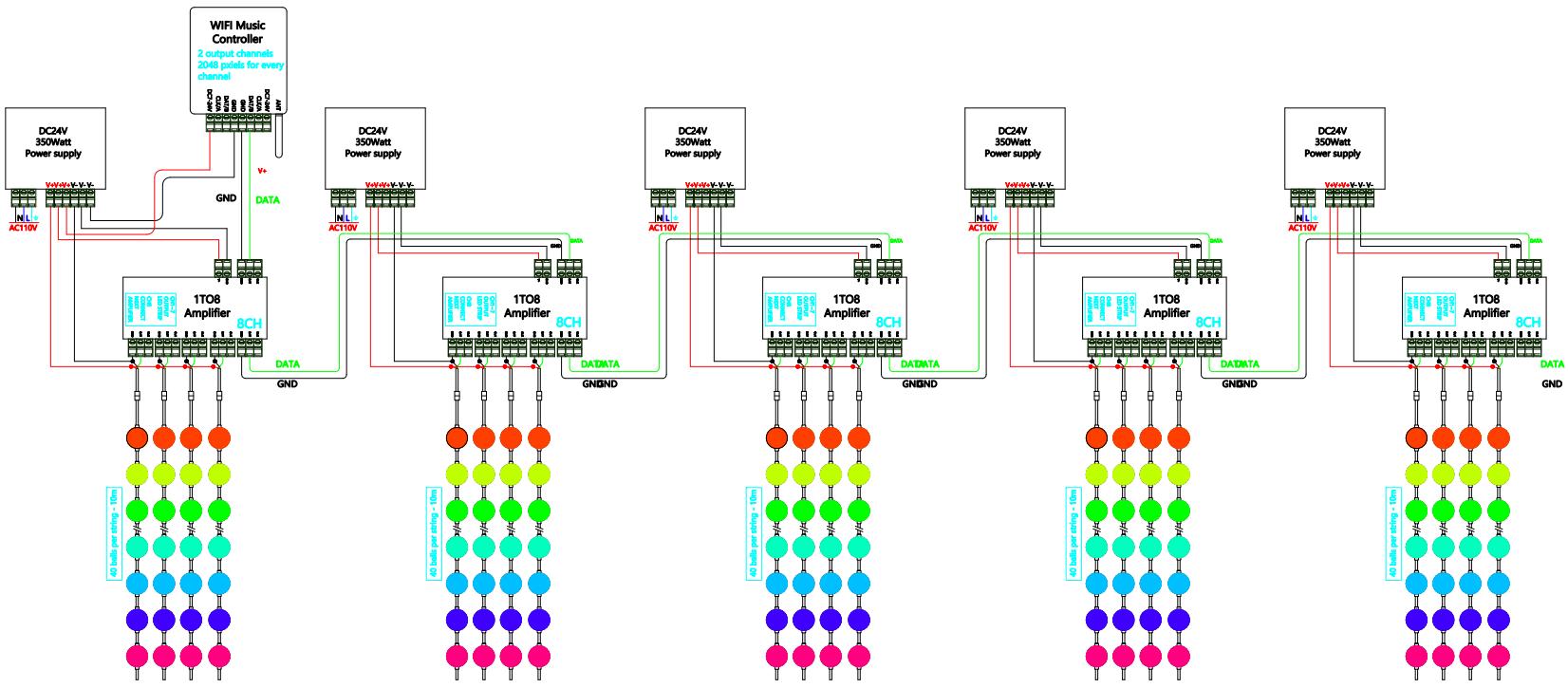

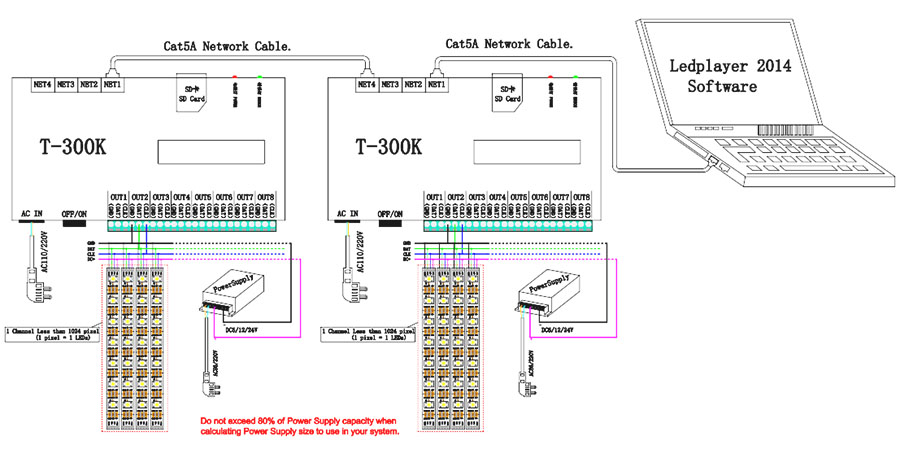

►Color changing led strip lights should be controlled by the LED controller.

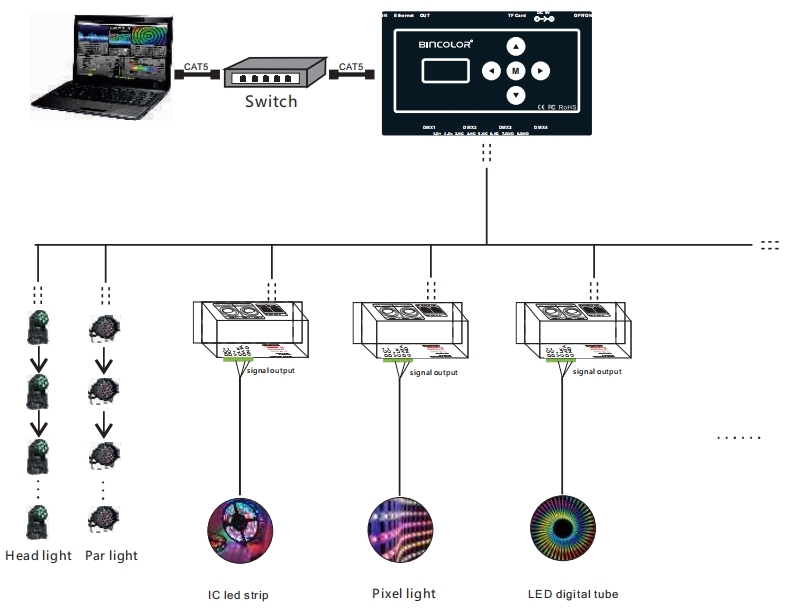

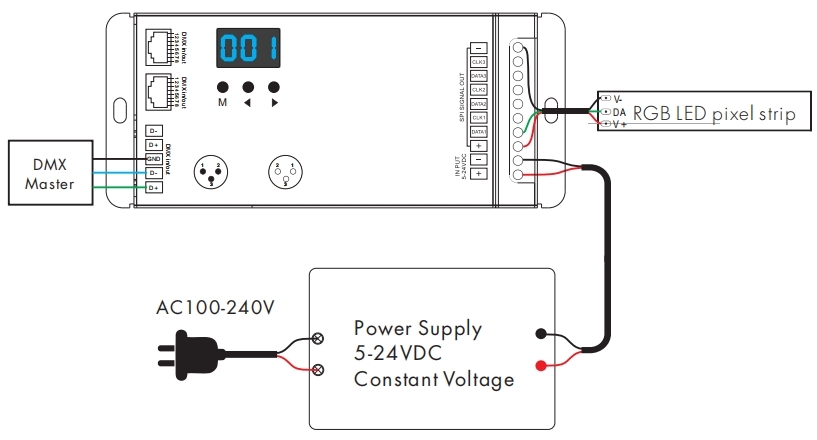

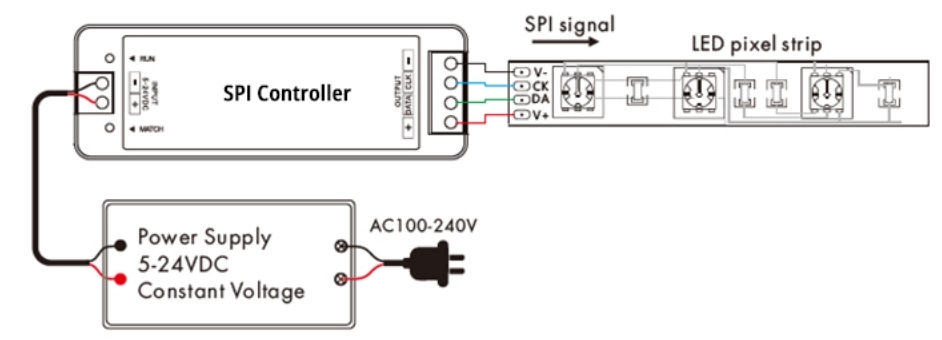

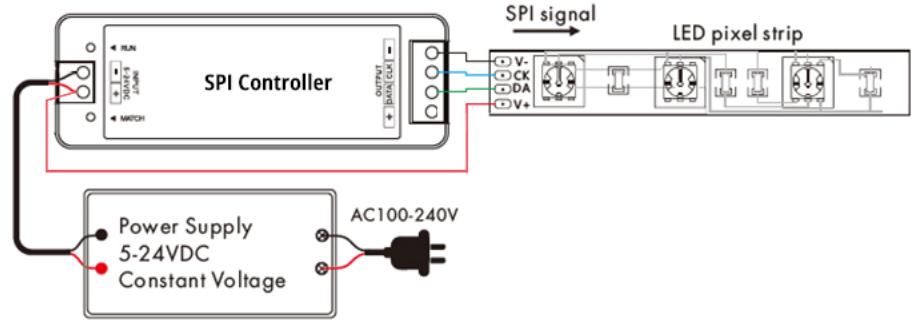

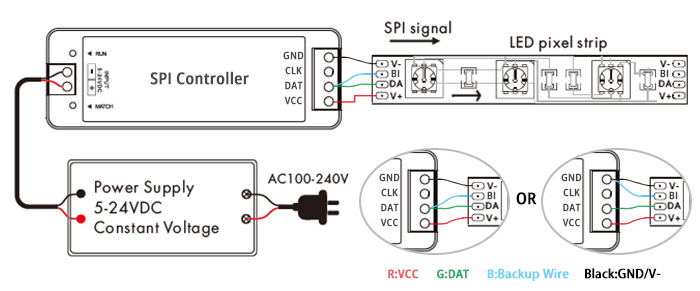

WIFI led controller, RF led controller, IR led controller, Bluetooth led controller, and addressable led controller such as DMX512 series and SPI controller are all mentioned in the article about led controllers. Note that the led controller channel cannot be less than your led strip channel. For example, an RGB led strip has 3 color channels, and an led light controller with 3 or more channels should be selected.

When installing the led controller, the power of the controller and the power supply must be the same.

Related: How to choose the led strip light controller?

How to wire single color led strip lights?

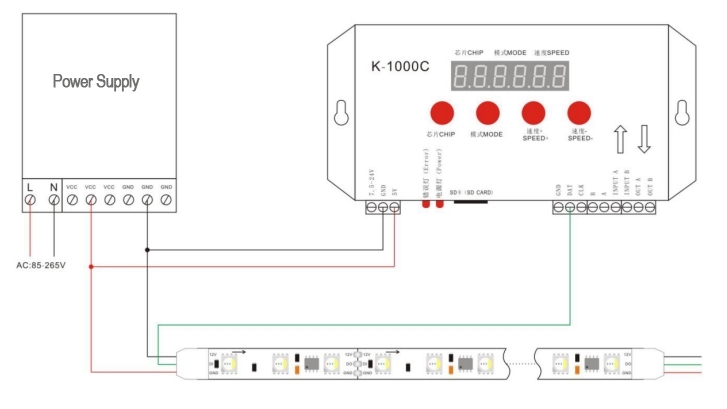

6. How to power the LED strip light?

The led strip light needs the power supply to work. Choosing a suitable power source for your led strip is extremely important. The working voltage of the led tape light should correspond to the output voltage of the led power supply. Triac dimmer and 0/1-10V dimmer should choose the dimmable led driver. For waterproof or outdoor use, choose the waterproof or rainproof power supply. And constant current led strips can only use the constant current controller and the constant current power supply.

There is one rule that must be followed about power wattage when choosing an led power supply, that is, the 80% rule. Four simple steps to teach you to calculate the power you need, click on the article link to view.

Related: How to calculate the led strip power you need?

How to connect led strip to the power supply?

In conclusion

First determine the color of your led strip, whether it is a single color, multi-color, addressable dream color, or led neon light. Click into the relevant category to select the appropriate voltage, PCB width, density, and waterproof level for your light strip. Then choose the matching led controller and led driver according to the determined led strip.

If you have other questions about the choice of led strips, please feel free to contact us.

What you need to know about led strip installation

How to connect two light strips together?

How to wire single color led strip lights?

How to wire tunable white/CCT led strip lights?

How to wire RGB color changing led strip lights?